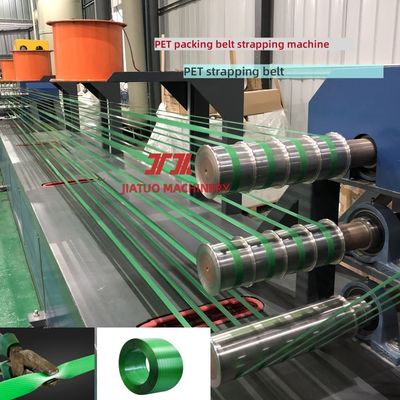

Macchina di estrussione per la produzione di nastri di imballaggio in plastica in PET completamente automatica con sistema di filtraggio automatico

Flusso di processo della linea di produzione di nastri di imballaggio in PET

①Material→②Stirring raw material→③Pre crystallization drying→④vacuum dehumidification→⑤Extruding→⑥cooling and forming →⑦ oven pre-heating →⑧ primary stretching →⑨secondary stretching →⑩ embossing → ⑪oven shaping→⑫ cooling→ ⑬avvolgimento (prodotto finito)- Sì.

Parametri della macchina di produzione di PET da 1 a 2

| Articolo | JTPET-90 |

| Progettazione della vite | per la fabbricazione di apparecchi per il trasporto di merci |

| Le cinghie Qty. | 2 cinture |

| Prodotto/giorno | 5.5-6T/24 ore |

| Fanculo Dia. | 90 mm |

| Winder Qty. | 2 serie |

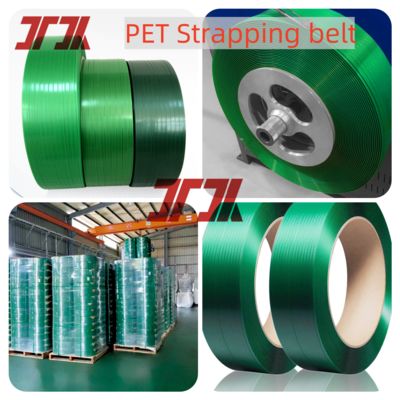

| Materiale utilizzato | 100% di fiocchi di bottiglia riciclati/materiale vergine/miscelati con |

| Potenza di funzionamento | 110-120 kW |

| Potenza installata | 200 kW |

| Specifiche delle cinghie | Larghezza 9-32 mm spessore 0,6-1,2 mm |

| Zona dell'atelier | L (55m) ×W (2m) ×H (8m) |

| Componenti elettrici | Schneider |

| Materiale | Materia prima in PET o fiocchi di bottiglie in PET al 100% riciclati |

Caratteristiche della macchina per la produzione di cinghie in PET

1.Screw con rapporto di compressione specialmente per PP/PET, con graduale variazione di diametro e scanalatura del filo più profonda nella parte di fusione.

2. scatola di ingranaggi con ingranaggi induriti; la matrice può essere regolata con precisione per garantire una produzione stabile e una superficie liscia delle cinghie.

3.Dosaggio preciso e miscelazione delle materie prime.

4.Precalda e asciuga circolando automaticamente.

5.Plastificazione uniforme, estrusione stabile e controllo preciso della temperatura.

6- Un grande dispositivo di allungamento con forza di trazione e un forno di riscaldamento isolato.

7Serbatoio d'acqua in acciaio inossidabile di grande capacità, controllo automatico del livello del liquido.

Prodotti finali di fasce di PET/linea di estrusione per cinture/fasce di PET/macchina di estrusione per cinture

Domande frequenti

D: La vostra azienda è fabbrica o società commerciale?

A: siamo fabbrica, siamo impegnati in questo business da 30 anni, abbiamo anche la nostra fabbrica di cinghie PET PP.

D: Qual è la procedura quando si acquista la nostra macchina?

A:Confirm the technology and machine configure -----confirm price----sign contract and make PI---send down payment - start to make machine---inform you before machine finish-you come our factory to check the machine---you accept the machine ----finish payment-exporting---send our technicians to your factory install the machine---answer your question all the using time and supply spare parts with cost only.

D: Puoi garantire la tua qualità?

R: Certo. Siamo la fabbrica di produzione. Ancora più importante, mettiamo un alto valore alla nostra reputazione. La migliore qualità è il nostro principio in ogni momento. Puoi essere completamente sicuro della nostra produzione.

D: Qual è il termine di pagamento?

R: Il modo migliore per entrambi è il deposito del 30% T/T e il pagamento del 70% T/T prima della spedizione, poiché testeremo la macchina prima della spedizione.Si può scegliere il modo più conveniente (termini di pagamento): T/T, L/C, Western Union ecc.)

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!

Rating complessivo

Rappresentazione del rating

Di seguito è riportata la distribuzione di tutte le valutazioniTutte le recensioni